VA, trades to turn up the steam

Date Posted: February 3 2012

BATTLE CREEK – A modern source of steam is on the way to heat buildings on the far-flung 200-acre campus encompassing the Veterans Administration Medical Center.

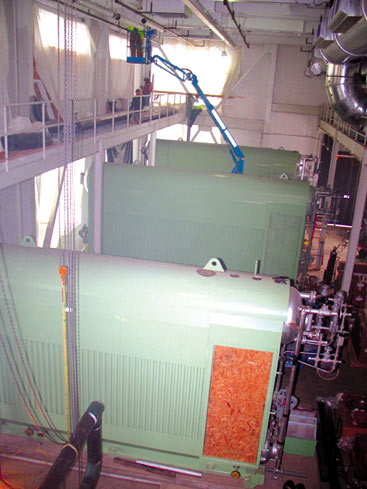

DeMaria Building Co., its subcontractors and the building trades are replacing the existing, inefficient, half-century-old steam system that’s struggling to keep up with the system’s demands. The three new modern boilers and steam lines are sure to save the VA big bucks on energy costs.

The brick-clad, 11,366-square-foot building housing the facility’s three new boilers is already in place. Work began on the project in November 2010, and the transition to the new boiler system is expected in June. The entire project should wrap up in November – then another phase will follow.

“We’re focused on the mechanical and electrical aspect of the project right now,” said DeMaria Project Supt. Todd Ackerman. “The trades have been fantastic. John E. Green, Delta Electric, Roberts Steel, they’ve been great to work with. We’re making really good progress.”

One of the largest VA Hospitals in the state, the Battle Creek facility has been serving veterans since 1924. It opened as Veterans Hospital No. 100 as a 500-bed neuro-psychiatric facility on the grounds of Fort Custer. Today, services are available to more than 217,000 veterans living in a 20-county area of western Michigan.

The Battle Creek VA Medical Center consists of 104 medical and psychiatric beds, 32 residential rehabilitation beds, and 103 nursing home care unit beds. In addition, specialized services offered include a Palliative Care Unit, a Substance Abuse Clinic, a Post-Traumatic Stress Disorder Program and a Domicilliary. The medical center, spread over scores of buildings, offers a wide variety of health care services, which includes both inpatient and outpatient care.

The new heating system will take care of the needs of the campus for years to come. Three new natural-gas-fired boilers will supply steam to heat the VA campus. Two are rated at 40,000 lbs. per hour, the other at 20,000 lbs. per hour, and they are capable of generating 97 million BTUs per hour. They can be individually fired up or shut down depending on demand. A backup fuel-oil powered system is also being installed. The buildings on the VA campus are cooled via a separate system.

The new boiler house has been erected a few hundred feet from the old boiler house, which includes a landmark 150-foot-tall red and white painted stack. Plans call for the old boiler house to remain – but the stack will be demolished.

A major portion of the project will mostly remain unseen – a new utility tunnel will encase steam and condensate lines from the new plant. The 15-foot-deep concrete tunnel will extend about 500 feet to a vault, where the carbon steel pipes will tap into the existing lines for steam distribution throughout the campus.

“Everything about this job is designed to save energy and run more efficiently than the old system,” Ackerman said. “It’s expected to pay for itself over the course of time.” The VA has a “Made in the USA” rule requiring equipment and materials installed on the project to be American-made whenever possible.

When this phase of the project is complete, another one awaits. The VA is also undertaking construction of a new combined heat and power biomass boiler that will link with the existing system. The system will burn wood chips to generate steam and power at the VA campus. Some foundation work on the new biomass plant has been performed, but most bids for that project have not been let.

The project is one of a handful of alternative fuel systems that are being installed at VA locations in the country. Part of the VA’s mission is to make sure the facility remains up and running in case of an event that might interrupt normal fuel supplies.

“The most important VA commitment is to care for veterans and their families, and the Green Management Program advances this commitment by ensuring a healthy and sustainable environment, low-cost energy, and clean air for current and future generations,” said C.J. Cordova, acting director of the VA’s Green Management Program.

THREE NEW STEAM BOILERS at the Battle Creek VA Medical Center include two rated at 40,000 lbs. per-hour and one at 20,000 lbs per-hour.

THE OLD BOILERHOUSE and red and white, 150-foot stack. The stack will be demolished. In the foreground is a key element of the new construction: a utility tunnel that will hold steam lines extending from the new boilerhouse to a junction that will distribute the steam throughout the VA’s campus.

FITTERS Roderick Newcomb and Rob Thurber of UA Local 33 work on the domestic water system inside the new boilerhouse at the VA Medical Center. They’re working for John E. Green.