Pipeline had a lot of character - but it leaked like a sieve

Date Posted: November 23 2001

ROCKLAND - Wood and water don't mix? Yup, that's pretty much true.

Water always wins? No doubt about it.

Those two generally accepted engineering principles were clearly illustrated over the last few years near this western Upper Peninsula town, in the form of a deteriorating mile-long wooden pipeline that fed the Victoria Hydroelectric Station.

Numerous leaks in the pipeline prompted the owner, the Upper Peninsula Power Company (UPPCO), to replace it over the last few months with a new, coated steel pipeline that should remain leak-proof for the foreseeable future - but will undoubtedly have a lot less character.

"It got to be where the old pipe looked like a sprinkler," said Jim Mennes, who managed the project for Montgomery Watson Harza. "The maintenance on it was terrific. There were thousands of leaks every year."

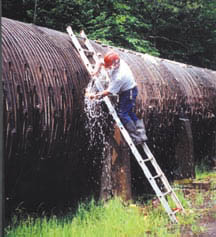

And how do you plug leaks in a 10-foot diameter pipe constructed of Douglas Fir? The one effective method was the use of wooden shims, which were tapped into one of the metal bands that surrounded the pipeline and usually sealed the leak. Workers would usually don rain jackets to do the work - the duty wasn't too bad in the summer, but Mennes said in the winter, "it was not a fun job."

The wooden pipeline, or "penstock," that was torn-out this summer was installed in 1959. It replaced the original pipeline that was built in 1929 to feed a hydroelectric generating station owned at the time by the Copper Range Mining Co. The pipeline's original 1929 steel bands, set 3 1/2 inches on center, stayed in service for 72 years.

The leaks had also deteriorated the pipeline's support saddles and foundation.

Building trades boilermakers, who have jurisdiction over penstock installation, as well as operating engineers, replaced the 6,050 foot-long wooden pipe with a 9.5-foot diameter, spiral-welded steel pipeline. They took care of the $6 million project working with engineering and site manager Montgomery Watson Harza and pipeline installation contractor Azco, Inc.

The pipeline extends from dam reservoirs on the Ontonagon River, down 215 feet to the Victoria Hydroelectric Plant. The downhill movement of the water places a maximum of 93 pounds per square-inch of pressure at the end of the pipeline, where 65-inch cast steel water wheels drive a spinning turbine to produce electricity.

The Victoria station's two units generates a total of 12,400 kilowatts. Owner UPPCO, a subsidiary of Wisconsin Public Service, supplies energy to about 50,000 customers in 10 of the U.P.'s 15 counties.

This isn't the last wooden penstock - Boilermakers Local 169 BA Babe Jenerou said there are still numerous such pipelines in the U.P. and around the nation. He said about 18 boilermakers worked on this project, as did several Operating Engineers Local 324 members, said BA Bill Gray.

"I guess I'm a little sentimental about seeing it go," said Mike Pederson, the project manager for Azco Inc. "It was an engineering marvel, the way the wood would expand under pressure and enhance the seal. It was really neat to see. I don't think there would be too many people who have the skills to make something like that today."

THE DAYS OF repairing leaks in the old wooden Victoria pipeline (above) are history. Below, Boilermakers Local 169 members working for Azco Inc. install the first section of new pipeline below the surge tank at the bottom of the pipeline, above the Upper Peninsula Power Co.'s Victoria Hydroelectric Station.